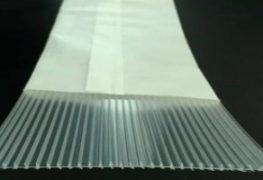

The prefabricated vertical drain was invented in the mid-1930s by Walter Kjelhnan at the Swedish Geotechnical Institute. The first drain consisted of two cardboard sheets glued together, with internal channels. The modern PVD consisting of geotextile filter-wrapped plastic with extruded channels was developed in 1971, also at the Swedish Geotechnical Institute. The plastic vertical drain allowed for faster installation and increased flow rate volume over the early cardboard style.

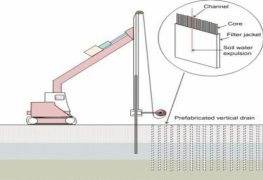

Installation Procedure…

Before installation can begin, the working surface must be prepared to ensure a stable working platform. Since vertical drain sites are typically soft, a sand or gravel blanket may be needed to provide support for the equipment. The sand and gravel will also act as a drainage blanket to direct water away from the treatment area.

Before installation can begin, the working surface must be prepared to ensure a stable working platform. Since vertical drain sites are typically soft, a sand or gravel blanket may be needed to provide support for the equipment. The sand and gravel will also act as a drainage blanket to direct water away from the treatment area.

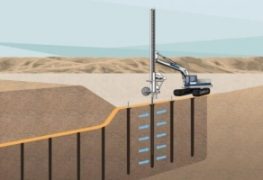

A specialized mast consisting of drain material and a mandrel is mounted on either a track-mounted excavator or crane, depending on the installation depth. Drains can be installed up to 140 feet deep from a track-mounted excavator. Drains deeper than 140 feet often require the mast to be mounted on a crane for stability.

The PVD is threaded through the mandrel, which protects it from damage as it is installed through the soil. The installation force is typically provided by vibratory hammers, static force methods, or a combination of these methods depending on the soil conditions. Water may be utilized to lubricate the mandrel during installation to reduce the friction on the mandrel. An anchor attached to the bottom of the drain keeps it in place during withdrawal of the mandrel. The drain is then cut several inches above ground, and a new anchor is fastened to the wick at the bottom of the mandrel in preparation for the next installation point.

Design Considerations…

PVD are typically used in soft saturated fine-grained soils, such as silts, clays, organic silts, organic clays, peat, sludges, mine tailings, and dredge fills.

Geotechnical Considerations…

PVD are effective in the following soil conditions:

- Moderate to highly compressible

- Low permeability

- Saturated soils

- Maximum past consolidation stress less than load induced stress

Somesiteandsoilconditionsthatrequireevaluationpriortodeterminingtheeconomicandtechnicalfeasibilityofwick drain systems include:

- Working surface stability

- Overhead and below grade obstructions

- Stiff to very stiff layers (may be addressed with predrilling)

- Softness of anchoring layer

- Site accessibility

Environmental Considerations…

Water removed by wick drains will need to be collected and treated if the in situ soils are contaminated. For contaminated sites, the drain design length should not fully penetrate into an underlying aquifer.

The geotechnical investigation should include continuous sampling to identify any sand drainage layers that may contribute to faster consolidation. Appropriate consolidation tests should be performed on the soft material strata to estimate the magnitude and rate of the settlement.

Our Prefabricated Vertical Drains (PVD) are made of high-quality Polypropylene resins imported from leading petrochemical companies of middle east countries, has delivered excellent final products and been applauded by the engineers of the implementing firms.

Product Specification…

Polymer PE/PP/PET

| Mechanical properties of Drain |

| Width |

ASTM D3774 |

mm |

95±5 |

| Thickness |

ASTM D5199 |

mm |

≥ 4 |

| Tensile strength MD |

EN ISO 10319 |

kN/m |

≥1.5kN @10% strain |

| Elongation at 1.0kN |

EN ISO 10319 |

% |

≤10% |

| Mechanical properties of Filter |

| Wide width Tensile strength |

EN ISO 10319 |

kN/m |

≥ 2.5 kN/m |

| Trapezoidaltear strength |

ASTM D4533 |

N |

≥ 120 N |

| Grab strength |

ASTM D4632 |

N |

≥ 500 N |

| Water permeability, VIH50 |

EN ISO 11058 |

mm/sec |

≥0.8 per sec |

| Opening size |

EN ISO 12956 |

µm |

≤ 75μm |